The Structural Skeleton of Your Building: How to Make the Right Choice for Century-Long Integrity?

Aluminum Profiles: More Than Just "Metal Bars," They Are the Invisible Champion Defining the Performance of Curtain Walls and Window Systems.

When people marvel at the crystalline clarity of a building's glass curtain wall or the fluid form of its facade, they often overlook the "skeletal system" that supports it all—aluminum profiles. Hidden from view, they fundamentally determine the building's aesthetic integrity, safety, durability, and energy performance.

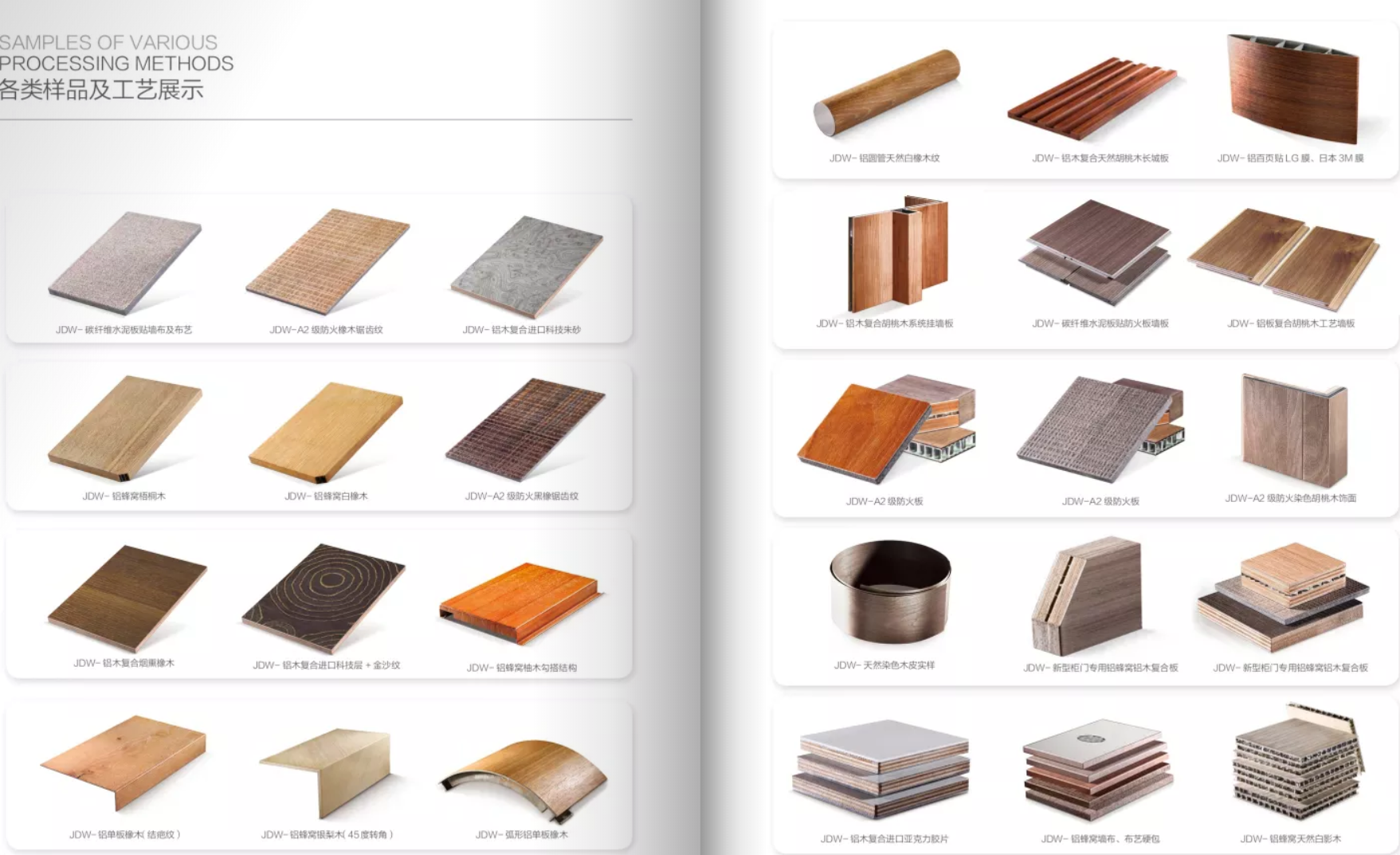

What Exactly Are Aluminum Profiles?

They are custom structural components made from aluminum billets, shaped through high-temperature extrusion, and finished with precision machining and surface treatments (e.g., anodizing, powder coating, fluorocarbon coating). They are not standard commodities but engineering solutions born to fulfill the functions of specific building systems.

Why Does "System Success Start with the Profile"?

- Core of Structural Safety: As the load-bearing skeleton of the entire curtain wall or window system, the profile's strength, stiffness, and design directly impact wind pressure resistance and seismic performance—the lifeline of building safety.

- Key to Energy Efficiency: The profile's cross-section design (thermal break structure) dictates the system's overall insulation. Superior profiles effectively block thermal bridging, reducing building energy consumption by up to 30% or more.

- Guarantee for Long-Term Use: Precise structural design ensures smooth drainage and airtight sealing, preventing water leakage risks. High-quality surface finishes provide decades of weather and corrosion resistance.

- Foundation for Production Efficiency: Standardized, high-precision profiles are the prerequisite for factory prefabrication and rapid on-site assembly, significantly shortening project timelines and reducing overall costs.

Core Application Areas:

Unitized Curtain Wall Framework: The "prefabricated skin" of high-rise buildings.

Primary Material for System Windows/Doors: The performance carrier for high-performance fenestration.

Skylight & Canopy Structures: Lightweight support for large-span spaces.

Interior Space Division & Decoration: Grilles and frames combining aesthetics and function.

Industry Insight:With the enforcement of mandatory standards like the "General Code for Building Energy Efficiency and Renewable Energy Utilization," using high-performance thermal break aluminum profiles has shifted from "preferred" to "essential." The market is moving from price competition to value competition centered on system performance, lifecycle cost, and technical service.

A Deep-Value Checklist for Engineering Decision-Makers:

We offer far more than just profiles; we provide technical support covering the entire project lifecycle:

Free Solution Consultation: We provide optimal profile cross-section and system recommendations based on your project's climate, design intent, and budget.

- Technical Support Documents: Complete profile calculations, detailed joint drawings, and test reports to facilitate your approval process and construction.

- Samples & Comparison: We send physical section samples for直观对比 of structural details, wall thickness, and surface finishes.

- Project Collaboration: We work closely with your design institute and facade consultant to optimize details and prevent construction issues. Inquire Now andReceive Additional Benefits:

- Benchmark Project Portfolio in Similar Climate Zones: Learn how similar projects maximize value through profile selection.

Dedicated Project Manager: Provides a one-on-one rapid response channel for you.

In a building's lifecycle, the invisible "skeleton" is often the most worthwhile investment.

Please contact us via LinkedIn direct message or visit our company homepage. Tell us about your project stage and specific needs, and we will immediately prepare targeted materials and solutions for you.

Content is based on current national standards and engineering practice. Specific technical solutions must be determined according to actual project conditions. We are committed to being your reliable engineering partner.